Case Studies

BETTER EPOXY PRODUCTS. SUPERIOR RESULTS.

We help organizations save millions and greatly minimize disruptions to their operations and the surrounding area during application. We make certain that our products are non-hazardous to applicators, communities, the environment, and aquatic life. These are the results that matter most to us.

Warren Environmental has proven our integrity and our products across the world, since 1996. Our products are time-tested. The results are powerful.

BROWSE OUR CASE STUDIES, AND LET'S WRITE YOURS.

Filter

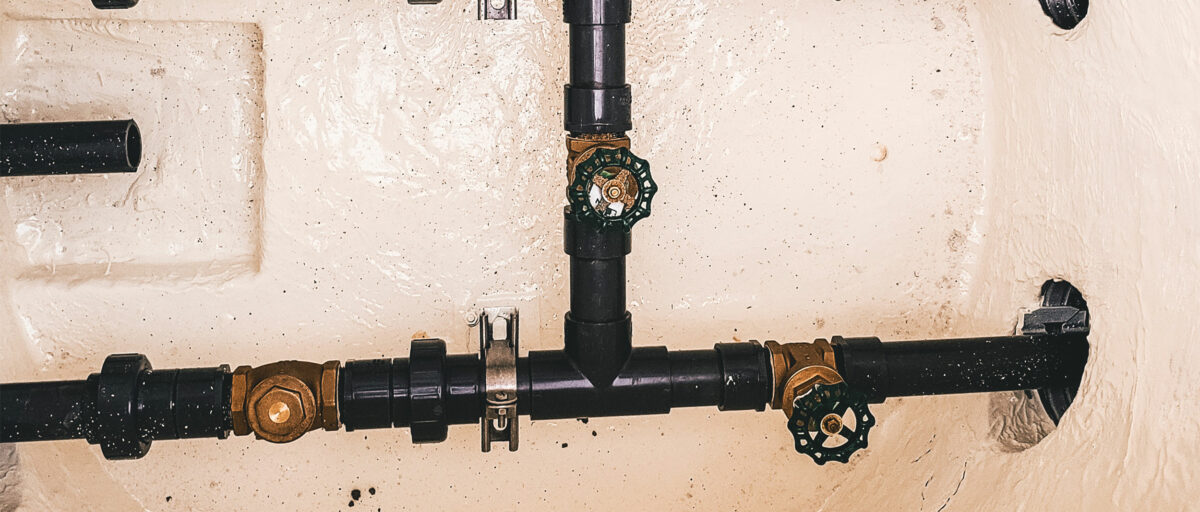

AC Hotel Pump Station Lining

Warren’s 301-14 epoxy coating protects newly installed pump stations for decades to come

American Water Clear Well Coatings

Warren’s BPA free epoxy extends the service life of a 90-year-old potable water clear well at a military base

Amtrak Subway Tunnel Lining

Warren's injection grout makes severely damaged train tunnel “like new” for Amtrak

Anaerobic Digester Tank Rehabilitation

Warren’s epoxy coating proves effective for severely deteriorated digester tank

Anheuser-Busch Plant Coating Projects

A client turned advocate due to our epoxies proven performance

Brick Arch Sewer Rehabilitation

Warren's epoxy coating system brings new life to a 100-year-old arched brick sewer

Brownsville Grit Basins and Influent Channel

Warren’s 301-14 rehabilitates and protects grit basins and an influent channel from high abrasion in humid conditions

Cast-Iron Outfall Pipe Rehabilitation

Warren's epoxy provides solution for aging cast-iron pipe in challenging environmental conditions

Charleston, South Carolina Distribution Water Main Pipe Repairs

SIPP Technology Minimizes Disruptions in Historic Residential Area

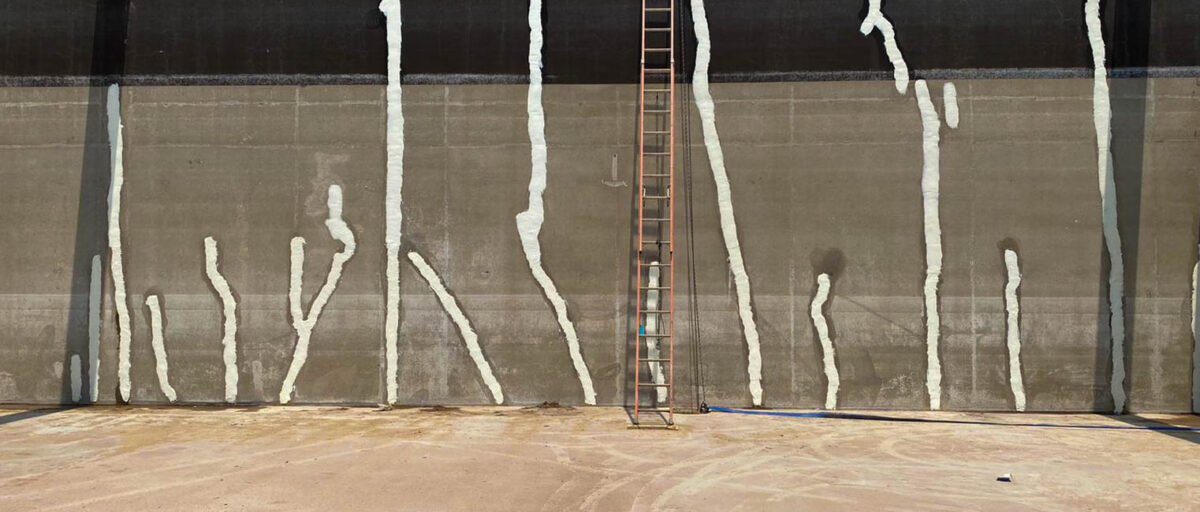

Cherokee Metropolitan District Water Reclamation Facility Crack Repair

Warren’s 301-14 epoxy mastic and 301-DF Duraflex provide timely crack repair in an existing aeration basin

City of Houston 24-Inch Cast-Iron Water Transmission Main SIPP Epoxy Rehabilitation

Spray-in-place pipe (SIPP) rehabilitation provides new life for critical water main in downtown Houston

Colchester Manhole Relining

Warren Environmental rights the wrong of a failed competitor’s coating

Concrete Reservoir Adit Tower Rehabilitation

Warren’s epoxy overcomes wet surface conditions within adit tower rehabilitation

Denver International Airport SAG Manholes

Timely rehabilitation of Concourse A manholes with Warren’s Duraflex epoxy for long-term, flexible protection

Duke Energy’s Crystal River Containment Coating Project

Warren Environmental, in collaboration with our approved applicator, performed turn-key coating services to Crystal River's nuclear site

Final Clarifiers Concrete Rehabilitation Project

Warren’s 301-14 restores clarifiers in the sixth largest wastewater plant in the U.S.

Goose Creek Interceptor Rehabilitation

Warren’s 301-14 epoxy coating provides schedule flexibility to save on bypass pumping operation costs

Gunpowder Outfall Sewer Transition Structure and Manhole Rehabilitation

Warren’s epoxy rehabilitates sewer while meeting aggressive schedule and minimizing disruptions

Holliday Creek Sanitary Sewer Trunk Main Rehabilitation

Applicator ingenuity and epoxy versatility result in successful rehabilitation for Wichita Falls, Texas

What would you do with

75 more high-performing years?

Save millions of dollars versus dig and replace.

Dramatically reduce downtime during application (just one coat) and throughout your asset’s extended lifespan – it will perform like new, reducing the need for repairs.

Protect workers, communities, and the environment by choosing a non-hazardous epoxy that is safe for use near aquatic life and for a variety of systems, including potable water.