Effective Spray Application: When Proprietary Epoxy Products and Patented Spray Equipment Combine

Achieving Warren Environmental's high build coating application in a single coat up to 500 mils

Written By: Brian Brandstetter, President

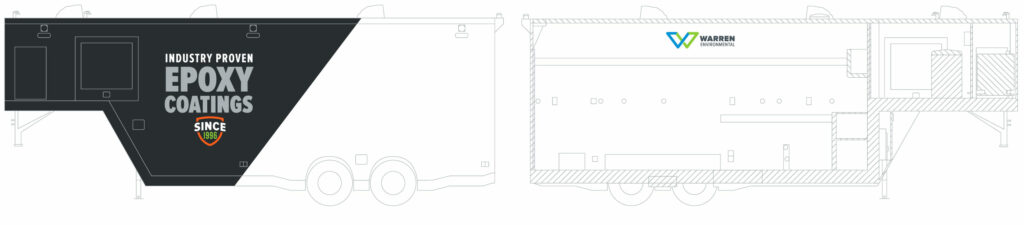

In recent months, Warren Environmental and representatives from our master applicator, A&W Coatings, were featured in an article on the history, development, challenges, and successes of Warren’s custom spray-trailer rigs. Here’s a breakdown of the interview on how A&W Coatings and Warren’s approved applicator network use a Graco pumping system in customized trailers to spray up to 500 mils of epoxy on their coatings projects:

History of Product Application

As a manufacturer of high-build, environmentally friendly epoxy coatings for the last 25 years, Warren provides epoxy products to its master applicator, A&W Coatings, and 21 additional approved applicators nationwide for use on municipal, industrial, and private entity projects.

Applied to a variety of different structures and substrates, for epoxy to be spray applied correctly, they require specific equipment. While Warren Environmental’s epoxy products themselves are critical to a project’s success, our coating can’t perform alone— our application technology and methodology are key. Our patented pumping equipment used to spray the product is equally as important, and when combined, it provides unparalleled results.

Danny Warren, founder of Warren Environmental, leveraged his years of extensive industry experience to develop his own proprietary epoxy formula, establishing a manufacturing facility by 1996. Not only did Danny invent a 100% solids, environmentally-friendly epoxy coatings solution free of solvents, but he created the patented spray equipment specifically designed to spray his unique formula up to 500 mils in a single coat. This spray equipment system was housed in trailer rigs for ease of application when transporting the product to a project site. After 25 years of successful application using the equipment and existing rigs, it was time to re-vamp the trailers to strengthen the effectiveness and consistency of product application.

Improving the Existing Trailer Equipment

Outfitting the updated custom trailer rigs with new technology was guided by feedback straight from the source—the applicator network. In charge of the maintenance and quality control of the trailer rigs, A&W Coatings reached out to its approved applicators for responses on their experience with the existing trailer equipment and improvement suggestions. The goal for the second-generation trailers? A simple, user-friendly design with efficient systems for safe operations.

The majority of applicators found the existing set-up to be complicated, inherently slowing down the process and increasing the learning curve when training new team members to run the equipment.

The lighting system was updated to include additional indoor and exterior lighting for safety. The use of space and layout of the trailer was also considered. The second-generation trailer includes new fuel cell integration for heavy equipment needed, such as an air compressor and generator for efficiency purposes. Other improvements included a large box frame and additional electrical hydraulic jacks.

To spray up to 500 mils, the trailer required a robust system capable of handling the product. Taking all factors into consideration, the XP50 Graco Sprayer was selected. A&W Coatings Project Engineer, Wesley Maples, was instrumental in selecting this new equipment and the overall trailer design. When explaining the reason for choosing Graco’s XP50 plural component sprayer, Wesley noted several benefits:

“The XP50 has a computer system, which allows it to maintain and monitor material ratios. We’re a two-to-one product. The computer system’s ability to shut the pump down if the material isn’t on ratio is a huge win because ultimately, the product has to be in ratio to go on correctly. It’s just another way we’re maintaining a quality standard. Not just any equipment will spray Warren’s product, but Graco’s XP50 worked out really nice.”

Research and Development of New Equipment

To stay up-to-date with the latest technology available in the industry, Warren began to research and develop the second generation of custom spray equipment. The system was created by applicators, for applicators, which helped determine the priorities when equipping the new trailers.

Warren contacted Graco to collaborate on selecting a sprayer to use in the trailers that would provide the best quality of work. Warren President, Brian Brandstetter, reinforced the importance of using a sprayer that would be compatible with Warren’s patented pump technology, reiterating:

“We also spent a good deal of time with Graco distributors on understanding what the best new equipment options were for our product. We have a 100% solids epoxy that requires specific equipment to spray. Warren is not a paint—it’s a coating. Warren also has its own patented pumping system inside the trailer that deals with other parts of the operation, but we needed to match it with the best piece of equipment on the market for our product.”

Since this initiative began in 2018, Warren has launched the updated trailers and the applicators have proven success in working with the Graco system on their projects. Warren will continue to look for opportunities for technical improvements when needed, always keeping quality top of mind.